by Tal Lomnitzer – Portfolio Manager

The JH Explorer series follows our investment teams across the globe and shares their on-the-ground research at a country and company level.

The Francophone Canadian province of Québec, nicknamed “La Belle Province” is known for producing maple syrup. In future I believe Québec will be known for its battery supply chain and contribution to supplying decarbonisation materials. On a recent trip, I visited a graphite project, an iron ore mine and a battery cathode materials factory. These are among the many resource companies that are enabling the transition to a lower carbon future, via the switch from fossil fuels to renewables and the electrification of transport, among other key decarbonisation themes. This is fuelling unprecedented demand for various minerals and metals such as lithium, cobalt, nickel and graphite, which requires investment and innovation within the resources sector and government initiatives to boost and meet this growing demand.

Québec is uniquely positioned to lead the way in battery production

Not only does Québec have critical resources like lithium, graphite and iron ore, it also has plenty of cheap, clean hydropower and ambition. There is abundant investment capital courtesy of a forward-thinking government that flexes the massive pension savings of the population to support industrial development via direct investment in companies or projects.

As a free trade partner with the US, Canada (and Québec in particular) is ideally positioned to produce both battery raw materials and the batteries themselves to feed US car makers as they electrify their vehicle offerings, spurred on by the Inflation Reduction Act in the US. This ground-breaking US legislation offers US$500 billion in new spending and tax breaks that aim to boost clean energy. These incentives are catalysing investments in domestic manufacturing capacity, encouraging procurement of critical supplies domestically or from free-trade partners, and jump-starting research and development and the commercialisation of technologies related to electric vehicles, energy storage, carbon capture and clean hydrogen.

A greener way of purifying graphite

Electric vehicle and stationary storage batteries require an anode and a cathode for current to flow. The anode chemistry varies, but generally includes lithium and some combination of nickel, manganese, cobalt, iron or phosphate. The cathode is made of natural graphite that has been micronised (broken into very fine particles), spheronised (made into uniform spheres) and purified. China currently dominates graphite production, producing 70-80% of the world’s graphite and 100% of the natural graphite used in lithium ion batteries, but that looks set to change. Nouveau Monde Graphite has discovered a deposit that contains large flakes of natural graphite and is testing a more environmentally-friendly approach to purification using chlorine sourced from a neighbour company, Olin at the Bécancour Waterfront Industrial Park. Several battery supply chain companies have announced plans to build capacity, which will require significant quantities of local graphite supply.

Graphite purification at Bécancour Waterfront Industrial Park.

A responsible miner providing social benefits

Iron ore too is going be required to make low-carbon footprint steel and about 700km from Montréal near the aptly named town of Fermont (or iron mountain), lies the Bloom Lake mine, which produces some of the lowest-carbon footprint, high grade iron ore available. The mine has a chequered past having gone bust under its previous owner but the current owners, Champion Iron, have turned the operation around, and through significant investment, production capacity has doubled recently. I wanted to see the operation for myself to understand how they turned a ‘sow’s ear into a silk purse’. My visit convinced me that not only is the company running things extremely well, but the mine is an important part of the local economy with a positive social impact, complementing the environmental benefits of the iron it sells.

Transporting iron ore in Fermont.

Sustainable battery materials to power electrification

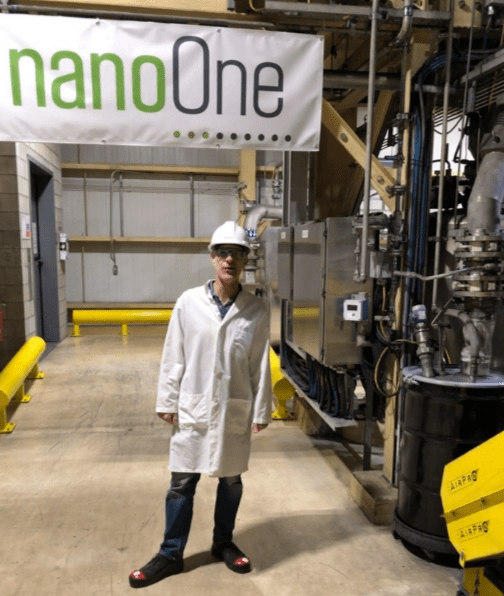

My final site visit was to a Cathode Active Materials (CAM)* plant. The plant’s new acquirer, NanoOne, plans to commercialise a patented process for making Lithium Iron Phosphate (LFP) battery materials in a way that is less energy intensive and produces much less waste than the competing method currently used in China.

It was minus 30 degrees Celcius when I arrived in Montreal, but what I saw and learned from my trip was certainly heartwarming. As they say in Québécois – C’est tiguidou (It’s good!).

LFP Cathode material plant in Candiac, near Montréal.

*Cathode Active Materials (CAM) are composed of lithium and metal, they have different characteristics dependant on the type and ratio of metals used, which determines the performance, efficiency, reliability, costs, durability and the size of a lithium-ion battery.